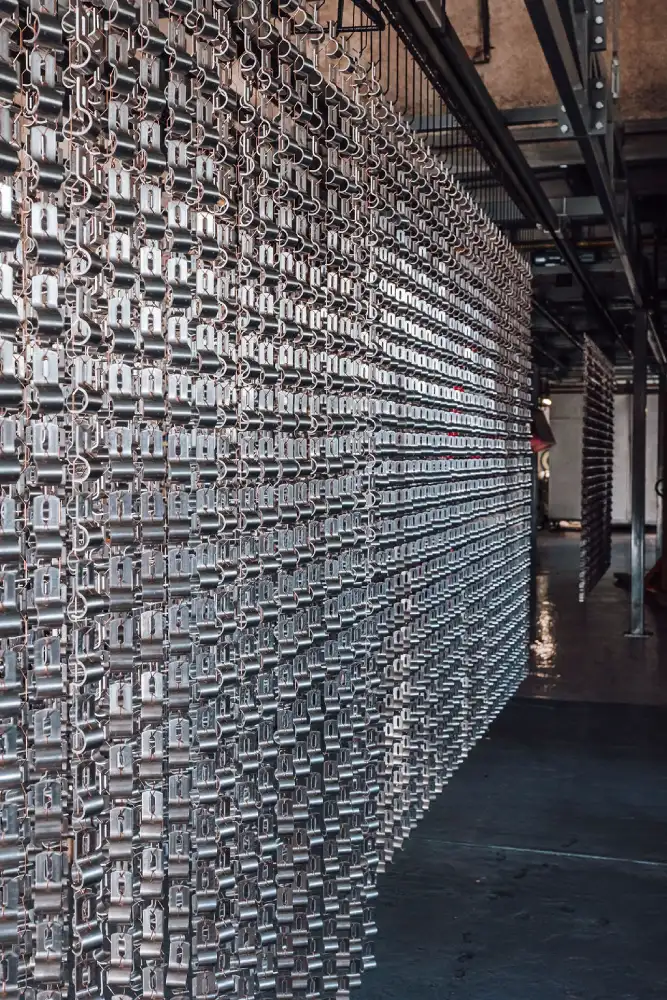

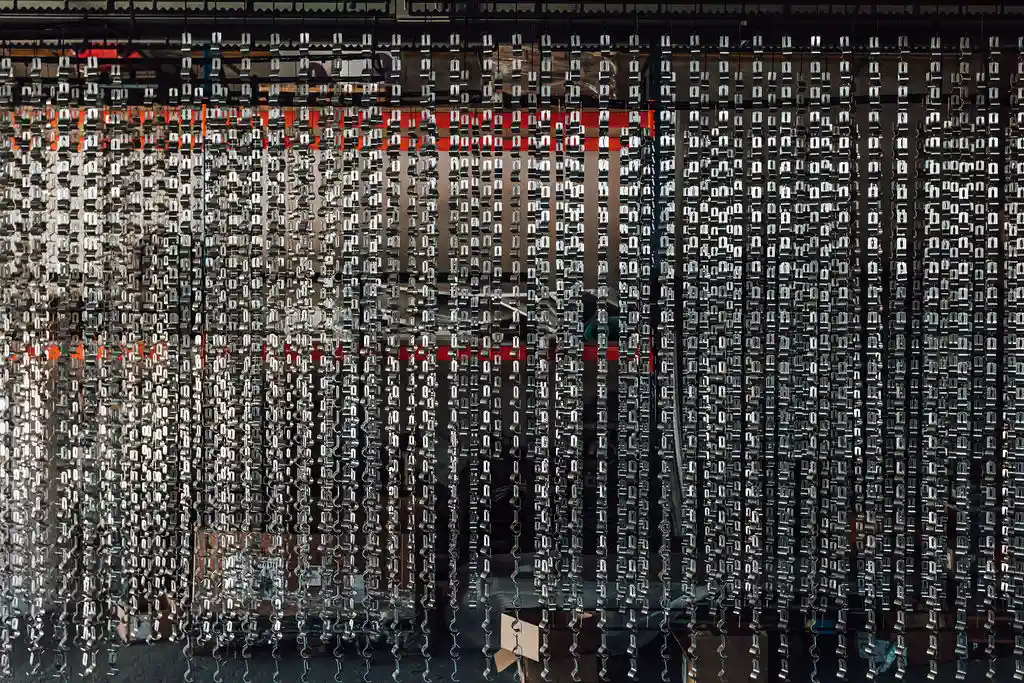

Aluminum passivation is a surface treatment process that creates a conversion chemical layer on the surface of an aluminum object. This layer enhances resistance to corrosion and stabilizes the electrical surface resistance. Aluminum passivation also improves the durability and long-term adhesion of bonded joints. Naturally, aluminum objects become more resistant to weather conditions and other environmental factors due to passivation. Additionally, passivation enhances their appearance. It is an effective prevention method that extends the lifespan, durability, and functionality of metals by protecting them from degradation caused by corrosion.

In our workshops (powder coating facility), we focus primarily on powder coating – comaxiting, and aluminum passivation, as well as other methods of metal surface treatment.

Aluminum passivation as protection for metal surfaces against corrosion

It is clear that aluminum passivation, much like powder coating – comaxiting, is a specialized process that requires not only appropriate materials and equipment but also professional expertise and knowledge. In our work, we use passivation agents known for their high quality and effectiveness. For further information, we are at your disposal.

We primarily focus on these services.

Aluminum Passivation Process

Aluminum passivation typically follows cleaning (thorough degreasing of the surface and removal of dirt, dust, oil stains, and other contaminants) and subsequent pickling. The pickling process is performed using pickling agents (gels, pastes, liquids) and serves to remove oxides, corrosion products, or discoloration. It is important to note that pickling removes a thin surface layer.

After pickling, aluminum passivation begins, forming the protective layer (passivation film) on aluminum objects. This occurs through the action of oxygen, water, and oxidizing acids, which coat the aluminum with a layer of oxide. This layer prevents further chemical reactions of the aluminum. Passivation is carried out by spraying or immersing the object in a passivation solution. Once the process is complete, the aluminum object is cleaned, inspected, and dried.

Questions and Answers – FAQ about aluminum passivation

What is aluminum passivation?

Aluminum passivation is a process in which a thin protective layer of aluminum oxide is formed on the surface of aluminum. This layer prevents further oxidation and corrosion of the aluminum, increasing its resistance to external factors such as moisture or chemicals.

How is the passivation layer formed on aluminum?

The passivation layer on aluminum forms naturally when aluminum is exposed to air. Aluminum reacts with oxygen to create aluminum oxide (Al₂O₃), which is stable and prevents further contact of aluminum with oxygen. This process can be accelerated through various chemical treatments, such as anodization.

What are the advantages of aluminum passivation?

The main advantages of aluminum passivation include:

– Enhanced corrosion resistance

– Protection against oxidation

– Improved surface stability

– Better adhesion for paints and other surface treatments

Does the company BJ POWDER s.r.o. also hold an ISO certificate?

BJ POWDER s.r.o. holds the ISO 9001:2015 quality certificate and operates two spray lines – a new Romer line in Smolenice (Slovakia) and an automatic high-capacity line in Senica (Slovakia).”